Unhappy kitties......

Message boards :

Number crunching :

Unhappy kitties......

Message board moderation

Previous · 1 . . . 3 · 4 · 5 · 6 · 7 · 8 · Next

| Author | Message |

|---|---|

|

Dena Wiltsie Send message Joined: 19 Apr 01 Posts: 1628 Credit: 24,230,968 RAC: 26

|

Maybe you could go all 'eco-friendly' and build a 'wind-farm'. On the other hand, how do you 'farm' wind....aside from having lots of people eat beans and produce Methane, which is then used to drive a generator, via a gas turbine? lol If I can't talk you out of the idea (it will be very costly), then you may want to look at this web site. I found it when I was looking into constructing a solar panel for someone who was going to be doing a large amount of camping away from power. It didn't work out so I never got around to building the panel. While I was checking the link, it appears they moved to here |

Al  Send message Joined: 3 Apr 99 Posts: 1682 Credit: 477,343,364 RAC: 482

|

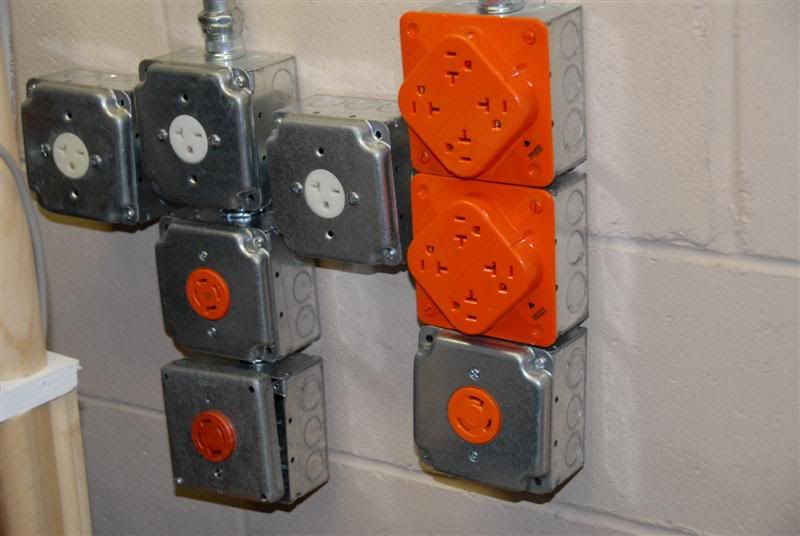

Yep, I know, one of the last details I will attend to just before I tie them into the breakers. I still need to feed a 30A 120 downstream run to my family room, putting in a big UPS there as well to protect my audio/video equipment. Just too many projects, but one by one, we're gettin there.

|

kittyman  Send message Joined: 9 Jul 00 Posts: 51515 Credit: 1,018,363,574 RAC: 1,004

|

Please remind me not to shut the rigs down in a fit of stupidity again. Both the Frozen Nehi and the 920 rig threw absolute hissy fits upon being restarted. The Nehi does it every time, and I know the workaround...it's stupid, but I have to go into the bios and change the data transfer rate, let it boot, restart, set the data transfer rate back up again, and it takes off. The 920 rig took almost an hour of coaxing to get it to shake off whatever was bugging it and finally start crunching again. Man, these OC'd beasts can be cantankerous. I hope when I do the power upgrade and finally get around to restarting the other 5 rigs they don't put up quite as much of a fight. Meow meow. "Time is simply the mechanism that keeps everything from happening all at once."

|

|

Dena Wiltsie Send message Joined: 19 Apr 01 Posts: 1628 Credit: 24,230,968 RAC: 26

|

Please remind me not to shut the rigs down in a fit of stupidity again. I suspect what you are dealing with is digital hardware is designed to work over a wide temperature range but to do that the clock speed must be reduced. When you bump the speed, you are trading off the temperature range the chip will function in. You have an additional complexity when you boot because the hardware is not generating the same amount of heat to keep you in that sweet spot. If it were any other type of hardware, I would recommend that it be constructed with Military grade parts which work over a far larger range. The problem is that Military grade parts have a very limited selection available and the cost is far more. If you could control the chip temperature better, I suspect you could start the system without altering the clock speed, but as it is, I think you have found the best solution to get things restarted. |

|

Iona Send message Joined: 12 Jul 07 Posts: 790 Credit: 22,438,118 RAC: 0

|

Please remind me not to shut the rigs down in a fit of stupidity again. Some years ago, there was the idea postulated, that, over-clocked CPUs, became 'imprinted' and I have found some evidence of this, personally. I suspect that what The Kittyman is dealing with is, given the nature of the 'shut-down', finding the BIOS settings that work for his particular use. Basically, he is starting from scratch (BIOS fail-safe, I suspect) and 'working it up' - many BIOS's simply revert to 'basic' settings - I've had this happen with my humble MSI Platinum P35 Express. Military spec parts? Biggest rip-off ever invented, by companies whose stuff was hard-pressed to be acceptable to large companies with high standards. In essence, all that 'miltary spec' means, is that it is tested a bit more. Where I used to work, we had 'military spec' materials, which were the same ones as used by Caterpillar, Solar Turbines, EMD, Garrett, Ruston Diesels, Alsthom, GEC, B&W and Wartsila...you get the picture. Sometimes, as my deceased younger brother pointed out, it meant, how each part was wrapped! Same material, same product, different wrapping paper, was about right. This is why a 'standard' stainless steel bolt for the military, costs several times (at least) more, than one you'll buy in a local hardware store! Don't take life too seriously, as you'll never come out of it alive! |

|

Wembley Send message Joined: 16 Sep 09 Posts: 429 Credit: 1,844,293 RAC: 0

|

Military spec parts? Biggest rip-off ever invented, by companies whose stuff was hard-pressed to be acceptable to large companies with high standards. In essence, all that 'miltary spec' means, is that it is tested a bit more. Additional testing is a valid requirement and a valid expense for certain applications. You wouldn't want the bolts holding the turret on your tank to sheer off in the middle of battle.

|

|

FiveHamlet Send message Joined: 5 Oct 99 Posts: 783 Credit: 32,638,578 RAC: 0

|

Just a little aside on the same vain. I decided that it was time to give the Rig on a Bench a dust down today. The Antec case that houses it allows the chassis to move out thus giving better access. The only problem is that the leads to the usb and 1394 sockets and others have to be disconnected. They are just not long enough. With leads duly disconnected I proceeded to GENTLY blow dry compressed air over it and into cooler fins. All went well until I came to reboot it. Just would not have it,all leads replaced or so I thought! I spent the best part of 2 hours taking leads of checking and double checking,I even cleared the cmos still no joy. Then I noticed 1 lead I had forgotten, the 4 PIN POWER LEAD to the mobo for the CPU. With that connected it booted first time. I did cuss a little but I have no one to blame but myself. Dave

|

|

Iona Send message Joined: 12 Jul 07 Posts: 790 Credit: 22,438,118 RAC: 0

|

Military spec parts? Biggest rip-off ever invented, by companies whose stuff was hard-pressed to be acceptable to large companies with high standards. In essence, all that 'miltary spec' means, is that it is tested a bit more. With any good company, with an active QC system, there should be no need, or excuse for additional testing. Testing batch components, should not incur an nth-fold increase in component cost, as often seen in 'military spec' parts. Turrets...the company I worked for, made the materials upon which turrets moved! The RMS Titanic is a classic example of pennies being saved, on the known use of inferior items to save cost...in that case, hull rivets. Big mistake. Don't take life too seriously, as you'll never come out of it alive! |

|

archae86 Send message Joined: 31 Aug 99 Posts: 909 Credit: 1,582,816 RAC: 0

|

With any good company, with an active QC system, there should be no need, or excuse for additional testing.When I got into semiconductors in 1974, the standard temperature spec range for military was -55 to +125C, compared to 0 to 70 for commercial, and the spec power supply voltage tolerance was 10% rather than 5%. If you think one can ship semiconductor parts to meet the military temp and voltage range differences alone based on passing the commercial part requirements with no testing verification at satisfactory quality level you are simply mistaken. Now, the question of whether you actually need the extra capability, in these or any other respects, is another matter entirely. Plenty of applications don't, including plenty of military applications which is one reason for the explosion in usage of COTS (Commercial Off The Shelf) parts preference in many military procurements. As to those insane profits from making mil-spec parts, they were insane enough that my employer exited the business. If the world's highest profit-making semiconductor manufacturer leaves a business, you can be sure they did not find it to be a gold mine for them. Again, some corners of the business may be making wonderful money charging a lot for nothing, but your generalizations are wildly free of the mark. |

RFP RFP Send message Joined: 21 Jan 10 Posts: 44 Credit: 29,197 RAC: 0

|

What is going on? Ghost in the code? Too many ions? Major sun spot eruption? MY UPS just went toes up. If you want it bad, you get it bad |

|

1mp0£173 Send message Joined: 3 Apr 99 Posts: 8423 Credit: 356,897 RAC: 0

|

With any good company, with an active QC system, there should be no need, or excuse for additional testing.When I got into semiconductors in 1974, the standard temperature spec range for military was -55 to +125C, compared to 0 to 70 for commercial, and the spec power supply voltage tolerance was 10% rather than 5%. I used to work in the defense industry. There is another factor, which explains things like $500 toilet seats. When a vendor supplies something to the military, they are required to provide things like tool kits, and they're required to have spare (replacement) parts for the supplied system, including tool kits and other supplies for the life of the system. If (let's say it's an aircraft) has a toilet, they have to supply toilet seats for at least ten years. ... and they cannot substitute. It has to be the same toilet seat design, manufacture and model as originally supplied. So, somewhere there is a warehouse full of toilet seats, purchased from the original vendor, of the exact "accepted" design. If there is a hammer in the tool kit, or a wrench, those parts are also stockpiled. Box after box of solder, and screws, and whatever else because it's cheaper to just stack 'em all up than to make a few later -- especially if the original manufacturer (the guy Rockwell bought hammers from) has an "improved" hammer and discontinues the old one, or simply goes out of business. |

|

solomon Send message Joined: 25 Jun 99 Posts: 5 Credit: 83,060,263 RAC: 0

|

"Then I noticed 1 lead I had forgotten, the 4 PIN POWER LEAD to the mobo for the CPU." I did the exact thing this weekend. Started building a new rig Thursday night and Friday powered it on. Everything spins up but nothing happens, no beep code, no boot. Looked at it a few times Saturday morning and finally took the whole thing apart. As I was taking the MB out I noticed the 4pin and slapped myself as I saw the power cable tied in the bundle with the other unused cables..... dave

|

kittyman  Send message Joined: 9 Jul 00 Posts: 51515 Credit: 1,018,363,574 RAC: 1,004

|

OK guys and gurlz.... Got a start on the power rewire... Bored the hole through the floor and strung 50' of the 6/3 through the basement. The length worked out just right. Will probably stub the cable into the main box and install the 50amp breaker tomorrow. Then I can start to assemble the branch cables and receptacle boxes. One question...I have gotten a bit rusty on this. At the mains, the neutral and ground are bonded together and also connected to the earth ground rods and the water mains ground. So really, neutral and ground are one and the same, and any of the lugs on the neutral/ground bus bars can be used for either connection. I believe the bus is bonded to the enclosure box as well. I seem to recall that there were certain situations where a in a subfeed box this was OK too....but sometimes it was not, and the correct thing was to have isolated neutral and ground buses. And I am not sure whether to bond the ground to the enclosure or not, although I think that was correct. If I need to keep neutral and ground isolated in the subfeed, I shall have to get an additional isolated ground bus kit, as the box only has 3 buses in it, L1, L2, and neutral. Any advice from somebody who is current on this? (No pun intended, sparkys). "Time is simply the mechanism that keeps everything from happening all at once."

|

|

Wandering Willie Send message Joined: 19 Aug 99 Posts: 136 Credit: 2,127,073 RAC: 0

|

Have you Tried reading from this site. It may explain what you are asking. http://en.wikipedia.org/wiki/Earthing_system Michael. |

kittyman  Send message Joined: 9 Jul 00 Posts: 51515 Credit: 1,018,363,574 RAC: 1,004

|

I was hoping that Al or hiamps might wander by and have the answer on the tip of their tongues.... Off to work now, mebbe they will check in whilst I am gone. "Time is simply the mechanism that keeps everything from happening all at once."

|

|

1mp0£173 Send message Joined: 3 Apr 99 Posts: 8423 Credit: 356,897 RAC: 0

|

I seem to recall that there were certain situations where a in a subfeed box this was OK too....but sometimes it was not, and the correct thing was to have isolated neutral and ground buses. And I am not sure whether to bond the ground to the enclosure or not, although I think that was correct. I'm sure this isn't the only case where it is important, but.... If the neutral and ground are connected in two different places, the two wire runs form a loop, and that loop has a resonant frequency. Among other things, it can act as an antenna and cause all kinds of strange problems with wireless devices and radio reception and etc. You can have (induced) current in the loop. The same is true if you ground the main panel and put a ground rod on the sub-panel. The loop is completed through the dirt. If you have a single point ground, you don't have a loop, and all of those issues, even if they're unlikely, become impossible. This is outside electricity and more about higher power (radio) transmitters, but ground loops become inevitable when you have a transmitter, an antenna, and a shielded (shield is grounded) feedline between them. The solutions are to change the length of the loop (change the resonant frequency) or to provide a second ground, AC-coupled (through capacitors) that is a different length -- one ground is part of a resonant loop. |

hiamps hiamps Send message Joined: 23 May 99 Posts: 4292 Credit: 72,971,319 RAC: 0

|

OK guys and gurlz.... You are correct, in a sub panel the ground and neutral must be separate. Lowes or Home Depot will have a ground kit. Make sure it is for the brand of Sub panel you have as they will have a few. Official Abuser of Boinc Buttons... And no good credit hound!

|

|

Wandering Willie Send message Joined: 19 Aug 99 Posts: 136 Credit: 2,127,073 RAC: 0

|

If in doubt refer to NEC 1996 edition at your local library. Fixed appliances on three-wire circuits In the USA, the cases of some ovens and clothes dryers were grounded through their neutral wires as a measure to conserve copper during the Second World War. This practice was removed from the NEC in the 1996 edition, but existing installations may still allow the case of such appliances to be connected to the neutral conductor for grounding. Note that the NEC may be amended by local regulations in each state and city. This practice arose from the three wire system used to supply both 120 volt and 240 volt loads. Because ovens and dryers have components that use both 120 and 240 volts there is often some current on the neutral wire. This differs from the protective grounding wire, which only carries current under fault conditions. Using the neutral conductor for grounding the equipment enclosure was considered safe since the devices were permanently wired to the supply and so the neutral was unlikely to be broken without also breaking both supply conductors. Also, the unbalanced current due to lamps and small motors in the appliance was small compared to the rating of the conductors and therefore unlikely to cause a large voltage drop in the neutral conductor. Michael |

kittyman  Send message Joined: 9 Jul 00 Posts: 51515 Credit: 1,018,363,574 RAC: 1,004

|

Thank you hiamps! So my old memory does retain a few things...LOL. Back to Meownards tomorrow to get an isolated ground bus bar kit. "Time is simply the mechanism that keeps everything from happening all at once."

|

RottenMutt RottenMutt Send message Joined: 15 Mar 01 Posts: 1011 Credit: 230,314,058 RAC: 0

|

mikeholt's forums confirms seperate ground from neutral on subpannel.

|

©2025 University of California

SETI@home and Astropulse are funded by grants from the National Science Foundation, NASA, and donations from SETI@home volunteers. AstroPulse is funded in part by the NSF through grant AST-0307956.